Time for a sailing blog!

Sometimes things get blogged and sometimes they don’t but, months after I last blogged about anything and nearly a year since I last talked about sailing here, the impetus finally comes from a September cruise I couldn’t have done when I was still working. Of course I’d thought that now I’ve retired I’d get fitting the boat out early for an April launch, but started building my kayak store instead before losing weeks of potential Fly time to dismal May/June weather and finally (if only narrowly) breaking my record for latest-ever launch in not hitting the water till 2 August! So was it worth it for what’s likely to be another sub-three-month season? With more good sailing already bagged by mid-September than perhaps the whole comparable post-refit ‘era’ of 2019 and 2021 (2020 of course being lost to lockdown etc.), I think that’s a rhetorical question…

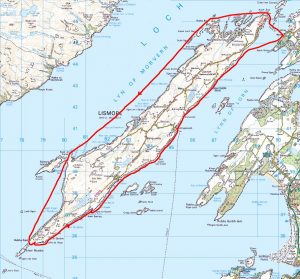

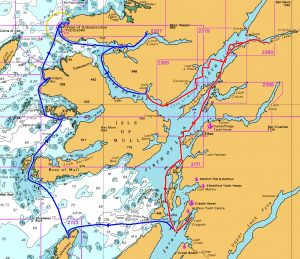

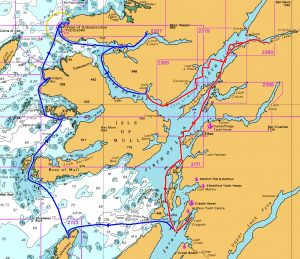

So I fancied a trip south, thinking Sound of Jura or something, and the combination of RHYC Loch Craignish muster on 3 September, proposed cruise in company to follow and weather looking OK for the foreseeable had me heading for Puilladobhrain on Thursday 1 September. With little wind till hints of a south-westerly tempted me into beating down the outside of Kerrera instead of motoring on through Oban Bay and the Sound, I didn’t get much sailing that day, but not to worry when there was plenty to come over the next week! See chart below for Fly’s track, with ‘solo’ days marked in red and ‘cruise in company’ in blue:

Can’t remember how many boats I counted at Puilladobhrain but it was certainly short of summer busyness at about eight (?), which helps when Fly needs a little more scope and swinging room than most as a light boat on part-warp rode when all-chain seems far more common. The yacht we followed in turned out to be Mark and Charmian Entwistle’s Discoverer of Sleat, likewise en route to the muster and cruise.

Friday was much windier, but gave good sailing all the way to Craignish once I took in a reef in the main and some turns on the genoa (setting beautifully with its padded luff) off Easdale, and arriving a day early gave me pretty free choice of anchoring spot within the designated area in the Lagoon (which actually never got busy with some boats preferring Ardfern in the strengthening winds):

While the muster was officially just Saturday evening, other RHYC boats were arriving all the time and I’d also purposefully got there a day early to see David and Carol Graham at Barfad, where we spent a very pleasant Friday evening as well as bumping into George Seaton at Ardfern when Carol took me up earlier to fill a couple of diesel cans. Then some serious threat (amber warning!) of rain caused the muster to be moved from the slip at the Lagoon to Lucy’s Ardfern (very nice café), where Vice Commodore Martin Clarke outlined the latest cruise plans (what… we’re still planning to go out through the Corryvreckan in this wind?), which might have led to a couple of boats heading elsewhere but turned out to be a good call. So we’re off through that notorious gulf on Sunday morning and of course I really wanted to do it (first time in all my years of west coast sailing), but it was windy and had been windy, if fairly crucially from the east with no sea to speak of. In the event it was probably about as straightforward as it ever gets and you’d never have guessed its reputation if you didn’t know… except that you have to know to be there at all! John and Lesley on Leumadair were through first, taking off at speed under full sail and quickly putting miles between themselves and the rest of us, with Fly following under just genoa (typically hitting the sweet spot for efficiency when single-handing in a breeze) and eventually being overhauled by the other bigger boats (Discoverer, YoHoHo and Warisha under various combinations of reduced sail) way out the other side. While my photos of Discoverer show her passing during the brief period Mark and Charmian shook out their reef(s), I think Warisha just had genoa all day and am guessing YoHoHo stuck with the genoa and tiny main you see:

Anyway, we’re through the Corryvreckan and heading for Kiloran Bay on Colonsay, which is providing excellent shelter from the east for us but wouldn’t from the west. I’ve not seen a yacht there in two short holidays spent at a cottage above the bay but there are going to be nine by nightfall, which might surprise those on the land! While Colonsay’s a lovely island and Kiloran’s a lovely bay, there are (many) times when neither’s the place to be in a yacht. This Sunday night it’s paradise afloat as well as ashore:

On Monday morning most of us are heading for Cragaig Bay on Ulva and, mindful that my thoroughbred 28ft cruiser racer is still by far the smallest boat in the fleet and I can’t drive her that hard on my own, I’m looking for a head start and away first again. Today I’ve chosen to start under just mainsail (still reefed from Friday), but the genoa might have been better when it’s almost dead downwind to Ardalanish, I’m not trusting the tillerpilot with the deep running angles and find myself preferring to steer by hand much of the way (NB the genoa’s not much use behind the main because it’s basically just blanketed and doesn’t want to goosewing). But it’s good, quick sailing and no-one’s obviously catching me apart from Geir and Deborah on Grand Banks 48 (motor yacht) Anne of Ardfern, who’d have overtaken me coming through the Sound of Iona if they hadn’t stopped for a break there.

Apart from that, it’s still a thrilling lone ride all the way to Cragaig on what’s now become more of a starboard-tack fetch with no real shelter from quite fresh conditions till I’m almost there, but I’m the first of the RHYC yachts to drop anchor just inside the single prior arrival whose poor crew probably thought they had the place to themselves!

So… Cragaig is a lovely wee harbour with decent shelter and a fine prospect of Ben More. While the entrance isn’t obvious from offshore till you’re really quite close, it’s actually quite straightforward once identified with a clean entrance channel that’s plenty wide enough. When (time to extricate myself from the present tense here!) I decided to pump up the kayak instead of the dinghy to try a wee paddle — and I mean ‘try’ because I hadn’t tried it from Fly before — I was surprised to see a group of sea kayakers appear from the corner of the bay and head off who knows where. Now I obviously can’t carry my sea kayak on Fly, but had brought the smaller of my two Gumotex inflatables, which is the really tiny Twist, and think I’d probably have preferred the slightly larger Safari. It’s a while since I’ve paddled the Twist and it does feel small, but at least I now know it’s possible to get in and out of an inflatable kayak from my hook-on plastic stern ladder and things should work better yet when I fit a more substantial folding stainless one.

Tuesday 6 September came with the twin targets of Calgary Bay for lunch and Sanna Bay for our overnight stop, we had good sailing all the way till the wind eventually (perhaps even conveniently?) dropped off the Point of Ardnamurchan and — wanting to get this blog done — I’m just going to leave the photos mostly to speak for themselves. But you might like to look out for the sailing ship off Staffa, the lifeboat (not sure which one) speeding past Lunga and my full mainsail, which had Fly absolutely trucking NNE towards Ardnamurchan after shaking out the reef as we left Calgary:

Now Kiloran, Calgary and Sanna have much in common as beautiful sandy bays popular with land-based visitors but open to the west in ways which leave them best classed as ‘occasional’ anchorages for seafarers… perfect in the prolonged easterly stream we’d been exploiting but potentially uncomfortable or even dangerous at other times. While Sanna also brought the first ever failure of my Rocna anchor to bite first time when trying to tuck right into the southmost corner with Leumadair and Anne of Ardfern simply brought up a humongous clump of weed, this was quicky rectified by moving slightly northwards to clean sand where RHYC member Doug Sharp coincidentally there on Blue Point had (like the solitary prior arrival at Cragaig) probably been anticipating a quiet night! And we had our first real daylight rain for days, with impressive afternoon showers to seawards (see photos of Warisha below) followed by a pretty wet evening for the beach barbecue we could have had dry any other night:

Wednesday saw our fleet starting to disperse, with Discoverer heading northwards home to Sleat and Neil, Sue and Mark on YoHoHo also deciding not to head up Loch Sunart as far as Salen. So we had just Warisha, Leumadair, Anne of Ardfern and Fly left that evening for a good meal at the Salen Inn although that’s somewhat jumping ahead when we have another pile of photos to take us there first! Again not stopping to say much about these when I’m trying to get the blog finished and it’s really just a peg to hang the photos from, but I do like the one of Martin motoring the dinghy apparently out to sea to say goodbye to Mark and Charmian as Discoverer departs:

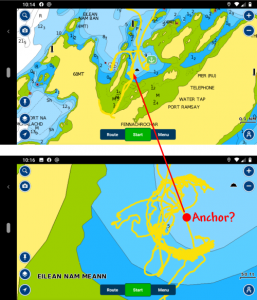

While I like anchoring and wouldn’t want to be simply sailing from marina to marina, pontoons also have their place and I enjoyed the change of gear that came with our final two nights at the fine facilities at Salen Jetty and Lochaline Harbour. So, yes, there are fees when anchoring is free, but you’re never going to drag, can step ashore, get toilets, showers, water, fuel, whatever, as well as instant, inter-boat socialising. And, after having previously been invited aboard Leumadair and Warisha for group drinks, it was nice to finally get John and Lesley aboard Fly at Salen and (jumping ahead again here!) Martin and Philippa at Lochaline. But our remaining group of four boats, seven sailors became just two boats, three sailors for Lochaline as John and Lesley on Leumadair headed off first on Thursday morning to catch tidal gates south and Geir and Deborah on Anne of Ardfern (who had been coming with us) had to go to Oban instead. The healthy breezes that had provided almost non-stop sailing from Craignish to Ardnamurchan were becoming more sporadic and my initially fairly determined attempt to sail finally gave way to a calm motor down the Sound of Mull about halfway between Calve Island and Eileanan Glasa or rather more than halfway between Salen and Lochaline. And here I had to stop and make circles to recalibrate the tillerpilot since I wanted to use it but something had started upsetting it as I’d left Salen that morning to the extent that it now simply wanted to steer an imaginary slalom course sweeping from lock to lock!

So I’ve already said I had Martin and Philippa aboard at Lochaline, but must add that was simply the prelude to an enjoyably long evening of dinner, music, wine and chat aboard Warisha with them… strange to think I’d never met them before Craignish, but that’s what a cruise in company’s all about when the people you’re with (and this includes everyone named above) quickly seem like old friends! Sad that dinner pretty well started with the news about the Queen, but we’re surely all aware growing older that none of us are here for ever. And we’re also reaching the end of my cruise tale now with Lochaline but a relatively straightforward day from Fly’s Glencoe home, or so I thought with favourable tide the whole way and the probability of a light north-easterly suggesting a pragmatic, quiet motor up Loch Linnhe to be sure of getting to the Ballachulish Bridge on time. In the event I had significantly stronger headwind than expected and set the genoa for some (mostly) motorsailing beating that would be both more comfortable than bashing straight up on engine and quite simply less hassle than a full-on sail against that wind on this final day:

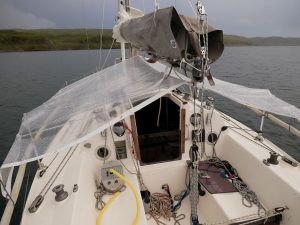

So what else needs saying before I wrap this up? While I’ve been an RHYC member for many years, I’d never joined one of these cruises before and it won’t be the last! Like the Drascombe rallies and group cruises I used to enjoy from 1992–6 (and on which we sometimes covered as much or more ground) but with bigger boats. It was good for me as Fly’s first real trip in years when I might have been feeling a bit rusty, but you don’t simply forget how to do things you’ve done for so long and it quickly just seemed so natural to be ‘back’. I’ve had a really good chance to test things (including, but not limited to, my new Raspberry Pi chartplotter and sprayhood) for the long-planned Shetland trip and now have a very good idea of what’s ready, what’s not and what I still want to sort or add. Perhaps I’ll discuss some of this stuff in more detail another time when things I’ve discovered about its usage may interest others, but right now I’d prefer just to say thanks to all the other participants (including those on Pride of Erin and True Brew who weren’t with us for so long and I barely saw) for such a good week together! :-)