Three blog posts ago, I mentioned my ‘diminishing, but by no means empty, list of ‘pre-launch’ and ‘later?’ jobs’. So, now Fly’s afloat, has been sailing and worked on some more, it’s good to report that just one ‘pre-launch’ job remains (taking a pattern to make new washboards) and the ‘later?’ list has progressed close to what I can reasonably achieve afloat before the winter. But let’s start with fitting the mainsail and going sailing before the new lifelines (guard rails) were even made…

So here’s Fly at the pontoon on 2 August with the mainsail up, then down and covered (when flaking it down on your own is never easy, but patience, sail ties to hand and calm conditions all help!):

And here she is out for a wee sail on 5 August under main and No.3 in breezy conditions with just two crew (Peter Watt and me), showing some main outhaul and then obvious kicker applied as I moved about looking at the shape of that sail:

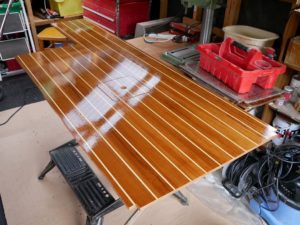

That morning, I’d fitted my new cabin sole and it got its first dent during our afternoon sail from unsecured, flying washboards in the cabin… my fault when I should know better, but it’s ultimately for walking on, not admiring, and you can’t actually see the mark here even though it’s in the photos:

My other slight gripe from the sail was ripping a wee metal badge off my new Dubarry boots, for which I blame Dubarry and not me for such a vulnerable and unneeded addition to expensive boots built to be used in situations where it’s almost bound to catch on something sooner or later (in this case sooner!). So I now have one with badge and one without, and have pondered without further action whether they’d both be better ‘clean’:

I’d also fitted new Lewmar winch handle pockets that afternoon before discovering that they really don’t take my new Harken handles comfortably at all, so also already pondering replacing them with something which does.

Getting back to more interior fitting out, the best place for the VHF mic clip was under the shelf, which required the angle drill I’d wanted for months so finally just bought:

I got that heads/main bulkhead door to work in both positions with the same catch body, but had to adjust the bit I’d already done slightly now the boat’s afloat and rigged before fitting the second small part. Fortunately the main part in the edge of the door was easy to adjust because its screw holes are short slots rather than just round:

The labels that came with the switch panels didn’t have everything I wanted so I started again with Dymo (actually done pre-launch). Quite tricky when the cutter on the Dymo will only give you three letters in the available width, but careful trimming with scissors gives you four and I’m OK with most of my abbreviations (not sure about H20, but didn’t like WAT, and not set on RA55 for STEREO, but thought STE or STER could get read as STERN). Also discovered the other night that the blue LEDs stop the cabin getting completely dark when switched on, so still considering ways to deal with that if necessary. The battery switches used to say ENGINE and CHARGING but Twig told me to change that after rewiring:

If I’d known the old socket for the starboard pilot berth bolt would no longer fit post-rebuild, I’d have had that wood block off before varnishing the bulkhead. But at least I got it off clean (thank goodness it wasn’t epoxied!) and can sort the varnish sometime. I made acetal discs to replace the original wood blocks with brass plates, but needed different thicknesses for port and starboard, with 12mm just right for starboard and 16mm (what I could get) adequate to secure the port bolt:

I tried to get the fly to face out for this photo but he/she/it was determined!

Yesterday I fitted the new lifelines collected from Owen Sails on Friday. For those not so acquainted with these things, the cord lacing forward is to help keep headsails on the deck when they’re down and the cushions aft for crew face-out on the rail (legs over the side and body between lower and upper lifelines) or just leaning against from the cockpit:

I’d spent much time pondering methods of securing the folded chart table, but sometimes simplest is best. That shockcord might not be as pretty as shiny hardware, but is much easier to fit and test, and probably does the job better with negligible tension sufficient to hold the table really firmly. You can also see the velcro-attached bookstop (not backstop!) to the right of the fuses, but you can’t put books up there (even flat) and sail with the chart table down because they just come flying over the fiddles. I’ll come up with a solution sometime:

Yesterday’s final act was to give the as-yet-unused water tank a final quick clean, throw in a purification tablet, half fill it with water, wait half an hour, pump some through, let the first wee bit drain through the sink, then drink a couple of mugfuls. And I’m still alive and well, which appears to be a good sign! It tasted a bit chloriney, but I couldn’t remember the tank capacity and might not have had enough water for the tablet, or perhaps it just always does (reviews seem to differ on this point)? Whatever, I’ll try adding some more water to dilute what’s already there and may not use tablet(s) with every refill, but am naturally still a little cautious of the unknown.

So where does that leave the ‘later?’ list? Some things were always going to be for next season once launch day caught up with them, like lining the underside of the main hatch (which somehow escaped getting done with the rest of the boat), finishing the cool box and sorting the rubber sealing strips under the cockpit locker lids. Others may get done if/when the opportunity arises, like fitting red film to the ‘chart table’ light. The Harken furler is operating as a headfoil, but not yet furling because leading the line aft from the drum (in the well) requires turning and through-deck blocks now sourced but not yet fitted. So that might or might not get finished afloat when establishing and at least marking the turning block position is the critical step while the rig’s up. And I’ll be seeing QD Plastics in Dumbarton shortly about nice new acrylic washboards, so might yet declare the blog ‘refit’ series done when I’ve got those because there’ll always still be things to do! The boat’s now essentially in commission and sailable, so we’ll see…