Last weekend Twig and I got some tricky Fly jobs done in lining the parts of heads, forecabin and coachroof where the liner’s stuck directly on (there are removable panels elsewhere) then refitting the companionway bulkhead facing, and were quite relieved to get through this lot with things looking good and no major mishaps. But some things turned out to be not quite so right when I returned in Tuesday’s snow to take the photos…

The heads and forecabin linings are fine when fitting and gluing the carpet to these tricky 3D shapes could so easily have gone wrong, but note that the edge above the heads door isn’t finished yet:

There was a small damp patch below the bottom right corner of the heads window (see the darker patch there?) that needs checking out because it’s a new window:

And you can see bright light off the snow getting through the topsides carpet (like the deckhead problem we resolved by painting first) to the lower left. So, while not planning to sail the boat through snow (!), I may still have to put up with some of this for summer sailing till I get the (exterior) topsides painted?

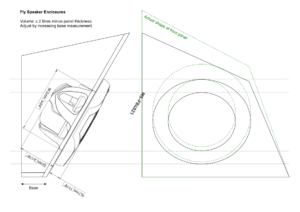

The bulkhead facing looks great in the photos but, despite two machine screws through the grab handle holes to line it up, is now firmly bonded a couple of millimetres below where it used to be. Not the end of the world, but still needing some thought in places. And, for those who’ve seen the cut on my forehead this week, the clamp to the left in the first photo is the one that attacked me when I ducked through the cockpit cover!

The most obvious problem (even if not obvious in my resized photos) is the porthole cutouts no longer being concentric, but I think that can be disguised with new liners where I’ve found a place that makes them for a reasonable price and can do iroko for a decent match to the teak. Not all of the screw holes line up and the compass cutouts are also slightly out, but will probably all be close enough, and I was already considering fitting a protective strip across the companionway bottom edge where it takes the most wear, but probably don’t have to for cosmetic reasons because the mismatch doesn’t look too bad there. Hindsight says we should have pushed the facing hard up under the hatch rails and used more screws for lining up when some of the holes through its thin plywood are slightly ovalled, but hindsight’s a wonderful thing when it’s firmly bonded with epoxy and Sikaflex and what could have been a ‘perfect’ job has turned out merely ‘OK’! :-/