To cut to the chase, we’re talking about a good day yesterday (something I’ve wanted to do for a long time) marred by stupidly knocking an unsecured camera bag containing my Lumix GM5 + 14–45mm lens in the water when I got out the packraft and almost certainly killing both!

It was of course entirely my fault; I have a waist strap on the bag, but didn’t clip it because I was wearing a buoyancy aid. The camera has a leash with a clip which I’d normally clip to something on me (e.g. rucksack), but didn’t because there are no obvious attachment points on this old buoyancy aid I took. Either would have ensured the camera left the boat with me or I could have just put it on the bank before I got out, but instead got out forgetting I had the bag there, remembered/looked for it, saw it floating alongside and thought ‘****’! It didn’t even take in that much water, but seems a little goes a long way…

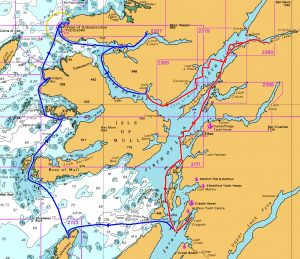

It’s over a year (July 2021) since I started looking at packrafts with trips like yesterday’s in mind. But I never got the Alpacka Llama I ordered in August 2021 for estimated January 2022 delivery because they sent the boat to the distributor in February with a ‘cargo fly’ or zip I neither specified nor wanted and simply haven’t agreed to put this right by supplying the boat as ordered for all the months since. So I finally requested a refund, went looking for something else and chose a Norseraft Loki Light which came within days. This is a simple open boat similar to the basic Llama, but perhaps even better for my long legs; Norseraft says ‘Loki Light is based on the design of the popular Viking Light, adapted for people up to 183 cm’, which should include me if height was the only consideration. But of course I have legs for someone considerably taller, so looked carefully at the specified inner length and sitting length (still more than the Llama) before putting some questions to Norseraft and deciding with Ørjan’s very helpful answers that I’d still get a good ‘performance’ fit with this boat. And so it’s proved to be when I’m finding my feet braced neatly against the bow for paddling with slightly bent legs and just enough wiggle room to straighten fully when I want.

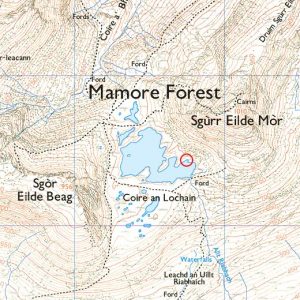

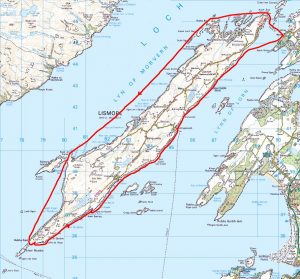

So yesterday’s trip was a local outing I’ve had in mind for at least a year, which was to paddle the sinuously attractive lochan sitting at c.735m between Sgòr Eilde Beag and Sgùrr Eilde Mòr that gives Coire an Lochain its name. And I probably visited every little bay more than once, criss-crossing the lochan for an hour and a half or so, both in and out of the wind which came and went. While I’d put in just west of where the Allt Riabhach leaves it, this floating exploration proved the best put in/take out spot to be some 120m north across the same eastmost bay, where a tiny inlet distinguishable on 1:25,000 but not 1:50,000 OS map seems to be the only place with a flat, sandy bottom instead of shelving (but at least smooth) rocks. My post-camera-dunking photo of the raft here was taken with my phone!

Time to post some more photos retrieved from the SD card in the GM5 before finishing with some more thoughts about the boat and the borked camera equipment. So here’s where I sorted myself out and put in, with Binnein Mòr behind:

And here I’m paddling north towards Binnein Beag (centre) against a breeze that’s stronger than it looks:

Here’s Sgùrr Eilde Mòr in a calmer patch followed by Binnein Mòr and Binnein Beag with the breeze increasing again:

Two shots not really doing justice to a rather nice rainbow up the west side of Binnein Beag, captured (I think) with the packraft’s stern sitting against the lochan’s bank:

And holding up my paddle below a new rainbow, which is the last shot you’ll see from the GM5:

So… further thoughts about the boat? It’s a good size for carrying to remote playgrounds, being big enough to paddle well (where its handling impressed me) but no bigger than I need for my legs. This particular model is a nice, almost bronze colour I find subtle but not dull (NB I did like the pale blue and gold Alpacka ‘Forget-Me-Not’, but am happy with this). It comes with a skeg/tracking fin as standard, which is good to have and I took with me, but chose not to fit on this occasion due to the nature of the shallow water round the lochan’s edges. I thought it handled just fine without, staying comfortably straight while paddling if making predictably slow progress against the strongest breeze! I started with my paddle at the 210cm I use for my other, narrower boats (sea kayak at 58cm and inflatables at 79/80cm) before trying 220cm in the breeze and reverting to 210cm, which still works for me despite the broader 94cm beam of the packraft. I found the seat and backrest comfortable although the seat’s considerable volume takes a bit of blowing up and some squeezing to deflate through its narrow, mouthblown tube. Fitting/removing the inflation bag for the main hull chamber is a bit fiddly because it screws into and out of the valve, which twists that end of the bag into a kind of ‘rope’ you then need to untwist, but the bag works fine when fitted. It’s clearly a well-made boat although mine did come with a couple of tiny marks to the tube fabric I’d prefer not to have found, but realistically it’s going to pick up marks in use and Norseraft’s extended my warranty since I reported them before using. While the floor’s lighter than that of the Alpacka I didn’t get, it’s the same 420D weight you get with most packrafts, seems sturdy enough and is surely a ‘compromise’ worth making for a boat that’s little more than half the price, easier to get hold of and seems to fit me better.

Now what about that camera gear? It’s all very well to save money on the boat, head straight for the mountain lochan I’ve wanted to paddle for ages and take the camera to document it when there are paddles I just don’t feel the need to document, but dunking said gear was a stupid and expensive mistake! It was a late decision to keep things as compact as possible by taking the GM5 instead of the G80 I’m thankful didn’t end up in the water instead, but then perhaps I’d not have missed the larger bag I have for that when I got out. Not that you get the choice with accidents but, if I’d had to choose which to wreck, the GM5 has been quite temperamental for some time now, suffering from a known fault where some hardwired little internal battery fails and you have to reset the clock if you haven’t used it for a while. Still an unfortunate loss as a neat wee body they don’t make any more, and also a pity about the 14–45 (the classic original Lumix kit lens), which was only on it because there’s an unrepaired (again known) problem with the zoom ring on the 12–32 that came with it. But I don’t use it on my G80 when I normally have the weather-sealed 12–60 fitted on that.

So is the dunked gear definitely dead? While it’s all currently sitting on/in rice in sealed containers because I have to at least give that a go, I think probably yes. While I might just get it dry and the electrics might just work if they’re not completely fried, things also feel a bit gritty from the sand I probably disturbed as I came in and got out. While I can also rationalise that it’s just stuff or point out the irony of it happening the day a new dry bag I got for strapping cameras to my kayak deck arrived, it’s above all a lesson in carelessness when it wasn’t having it in the boat that killed it but not taking proper care of it there!