From the title, it should be a long post. Thousands of pages long except that I don’t know how to fill them yet. The word ‘sea’ is ultimately superfluous when I’m just getting started with kayaks and have even less experience of, for instance, rivers and whitewater, but what I want to talk about because it’s where I’m currently wanting to go. So let’s start with what I’m learning so far and why what I still don’t know matters so much…

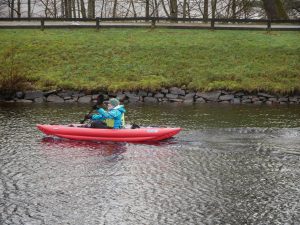

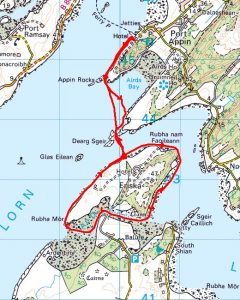

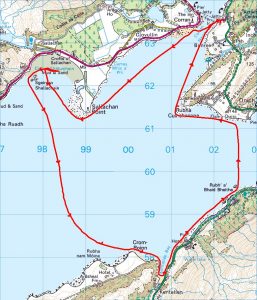

I’d booked a Sea Kayak Experience Day with Sea Kayak Oban and joined a family of four with instructor Erin for that on Thursday. We paddled out to the north side of Kerrera for lunch before returning to town, seeing an apparently well-known otter amongst other wildlife and features Erin drew our attention to. It was a great fun day, but I was still keen to start getting a feel for some more technique this side of winter and knew a one-to-one day now would be money well spent, so booked that for yesterday (Monday). But there are two more things I need to say about Thursday first:

- It started with a surprise in finding the boat I wanted to try most (North Shore Atlantic) after sitting in them the previous week in socks was not going to be the most comfortable fit in neoprene boots, so I took the P&H Virgo that first caught my attention and now at least know this one works for me on the water (I liked it a lot but obviously still need to try more).

- Before we went out, we practised removing spraydecks. Hands on head, down to the cockpit coaming, feel round to the tab and push up. Repeat a couple of times with eyes closed. I said I could probably find the tab without doing all that, but Erin countered with perhaps sitting here but how about upside down in the water? I’ll come back to that later!

Time to talk about yesterday now and there’s so much to say here, but of course you’re free to skim through it or simply stop when I’m setting it down primarily to consolidate my own learning and provide an accessible reminder of that for myself. My instructor for the day was Mark and we started by discussing what we hoped to cover. I’d jotted down a list which looked something like this without the bullet points:

- Fit (again)!

- Sweeps

- Draws

- Edging

- Braces

- Wet exit/reentry (if possible)

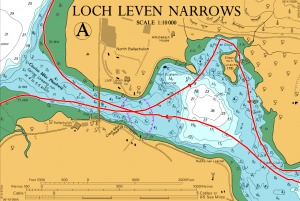

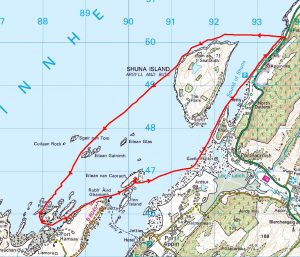

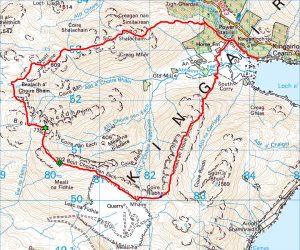

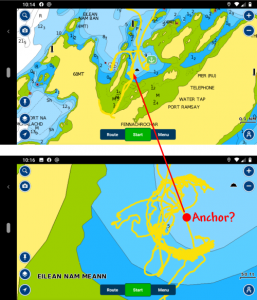

But we started with a discussion about maps, charts, wind, tides, sources of weather/tide information and planning the journey aspect of the day, where some things were obviously familiar to an experienced sailor and mountaineer, but others more kayak-specific, and I did note a couple of extra useful sources of weather info.

So what about fit? I’d think even most beginners know the importance of fitting the boat, but I was doubly concerned about finding a fit when my size, weight etc. says I should be in a medium volume boat, but my legs are so darn long and you don’t want to go high volume just for leg length when the boat’s likely to be otherwise too big. So we’re really looking for a medium volume boat that can take my legs, and thought we’d found three (P&H Virgo, P&H Leo, North Shore Atlantic) two Thursdays ago except that I was asked to remove my shoes to try them indoors, which turned out not to tell me everything I needed to know! So Mark had me (dressed to go this time) try these further boats to look at fit:

- His own composite North Shore Voyager 17.2, which fits different from the polyethylene Atlantic I’d tried, but still just didn’t work for me when I can’t get both feet on the pegs at the same time in boots… on which note he checked by looking inside with a torch.

- Zegul Arrow Play MV. This was another composite boat, but has a direct PE equivalent and was comfortable apart from the pegs meeting the arches rather than balls of my feet. So this might or might not work, but we didn’t take that one yesterday.

- P&H Scorpio MV, which a couple of friends have been pushing me to try and is certainly still a possibility, though this time with the pegs pretty well behind my toes and no obvious room to lift my feet.

- P&H Volan, which is a composite boat with no direct PE equivalent (Mark said the nearest thing would be the Virgo) but was the best fit of all. So he said something like ‘You’re paying for a day of private instruction, so might as well take the most expensive boat’ and we did!

Now, before we get to the actual paddling, I need to talk about spraydecks again. What we’d used on Thursday were ‘loose, nylon spraydecks which keep out the wind and water but will not trap you in the boat’, and Mark offered me the choice of one of these again or a standard, tighter neoprene type. So I thought for a moment, said I’d like to try the ‘proper’ one, he said good choice and I’ll, well, come back to that later! (Can you see where this is heading?) Then off we went…

The first thing needing attention was my forward stroke, where I’ve found good reasons to adopt a high-angle stroke for my Gumotex Twist but perhaps been overdoing it as shown by the Colonsay photos from my previous blog. So what we worked on was where the catch and release should be happening and when maximum power’s being delivered (early in the stroke) as well as keeping the top hand down and a tendency for the paddle to move off-centre in my hands that I already knew about and could also see in those photos. Then the next thing Mark taught me as we ended up off the north of Kerrera again was the stern rudder, which wasn’t on my list but I quickly found to be a very useful stroke. I had asked about draws and we moved on to these, but think that might have been after edging etc. which memory says we might have done next. While what happened in what order is already testing my recollection, I’ve not lost the key takeaways yet, so here they are before I forget:

- Bracing. By the time I specifically asked to look at bracing, Mark had already cleverly prepared the ground by having us holding on to each other’s boats, leaning the kayak over and bringing it back up… the key to doing so under control being ‘boat, body, head’ where the head’s the last thing to come back up and he also had me try bringing my head up first to feel the difference. Also reminding myself here that ‘boat’ is initiated by the lower thigh (the lower leg being known as the ‘water leg’) and the two further things I really want to remember about the low brace are bringing the paddle shaft close to my body and the sound of smacking the water truly flat with the blade.

- Edging. Mark talked about edge 1, 2 and 3 and we did edge 1 and 2. Edge 1 uses just lower butt cheek whereas edge 2 involves a ‘power triangle’ of lower butt cheek, upper thigh and lower foot, with the body kept upright through a combination of awareness, sighting the bow, squishing your upper side etc. And then there’s holding the edge, where I was surprised how much I had to work to get it and hold it, but never felt threatened by the kind of instability that comes with a simple lean. And turning while edging, where I already knew you can use either outside or inside edge, found I could do both but not adequately describe what I was doing differently for the inside edge, and Mark said he’s not going to tell me because he wants me to work it out for myself!

- Draws. On my list as something I’d tried and not found necessary for a 2.6m inflatable, but knew to be part of the essential sea kayak repertoire. But Mark surprised me by moving straight to the sculling draw, which he wanted to teach for the associated paddle awareness. So what have I got to remember here? 1. Hold the paddle at arms’ length across the boat. 2. Rotate my body so the paddle’s lined up alongside. 3. Slice the paddle vertically into the water. Then start to make the (pendulum) strokes before angling the blade to use the power and back faces… do this right or you’re pushing the boat away from the paddle instead of pulling it towards it (which Mark gave a name I’ve already forgotten), match the blade angles and get the elbow in the right place so you’re pulling sideways without added forward or backward movement, keep the movements small (‘less is more’) and keep your body rotated/looking in the direction you want to go.

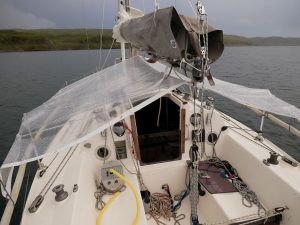

Now there’s already so much to think about there when all these skills ultimately need to become instinctive if you’re going to be able to deploy them just like that without stopping to break them down, but surely being able to depend on the right reaction becomes most important of all when you could drown if you can’t, and this brings us onto wet exit and that spraydeck. So we’re just west of Rubh’ a’ Bhearnaig at the north end of Kerrera with both kayaks afloat in a bit of a chop, and Mark says let’s do this here because it’s a realistic situation to stress the importance of the message, so I tip the boat up on cue but forget what Erin taught me about locating the spraydeck tab, can’t find it, unaccountably just stop looking, start relying on Mark to get me back up instead and, well, what a horribly valuable experience! To me, I’m upside down for ages (say 30 seconds) thinking I could be drowning today and why is Mark taking so long to get to me, whereas Mark says I was down for more like six seconds, my head was mostly above water and he was right there. So I screwed up completely, but now find myself oddly thankful for that scary experience because I’ll never let myself make the same mistake(s) again!

Having made such a mess of the exit that never was, it was important to try again and get it right, but this time we headed into the sheltered bay just east of the point, Mark put his boat ashore, waded back out not quite chest-deep to direct and got me to tip the boat twice with the spraydeck off before reminding me how to locate the tab and making me do it one more time with the deck on. And it just wasn’t a problem when I did it right; he also told me I’d have come out of the boat first time with the nylon spraydecks we’d used on Thursday, but I’m thinking I might have have missed my most important takeaway of the day without that unforgettable lesson in self-inflicted entrapment.

Time was moving on and we still had to get back to our starting point in town, so that was basically it and learning to get back in the boat after coming out of it will have to wait for another time. But I was already planning to book a two-day spring course, and have confirmed that I can now reasonably target the ‘Confidence Builder’ rather than ‘Introduction’ course. As we paddled back through Oban Bay I also asked about the availability of pool sessions and got some info about Oban Canoe Club, who I’ve since checked out on Facebook and their website as well as finding Nevis Canoe Club for myself. So I have people to meet and potential help both an hour south and half an hour north, and yet more to consider there.

To wrap things up for now, while I was always aware that sit-in sea kayaks present quite different challenges to open inflatables and what happens when you tip them up or fall out can define the difference between living or dying, we may consider that awareness now appropriately reinforced. While I know some suitably experienced sea kayakers sometimes paddle alone, they must be pretty darn sure they can deal with these things before their risk assessment squares. I didn’t need yesterday to tell me that, already knew that my kayak journey’s just beginning and fully understood the need for company for however long it takes, which could very well be always. For my inflatables, I see things slightly differently. If I choose to paddle one sensibly alone in a sensible place in sensible conditions at a sensible time, my risk assessment doesn’t have to be radically different from that of rowing my inflatable dinghy out to Fly. But I’m stressing ‘sensible’ where that’s informed by a lifetime’s experience of wind and water in other small boats, and not doing stupid things like heading for whitewater rivers or miles of open sea. So let’s just leave this blog where it started; while there are thousands of pages to be written on ‘what I don’t know about (sea) kayaking’, please rest assured that at least I know I don’t know it!